Articles » UV Curing Systems The Future of Fast, Clean, and Precise Curing Technology » OPTIMAX® UV-Cured Medical Device Adhesives

Biocompatible, High-Performance Adhesives for Critical Medical Manufacturing

At NovaChem UK, we understand that reliability, cleanliness, and precision are non-negotiable when it comes to medical device manufacturing. That’s why our OPTIMAX® UV-Cured Medical Device Adhesives are engineered to meet the industry’s highest performance and safety standards — including ISO 10993-5 and USP Class VI biocompatibility.

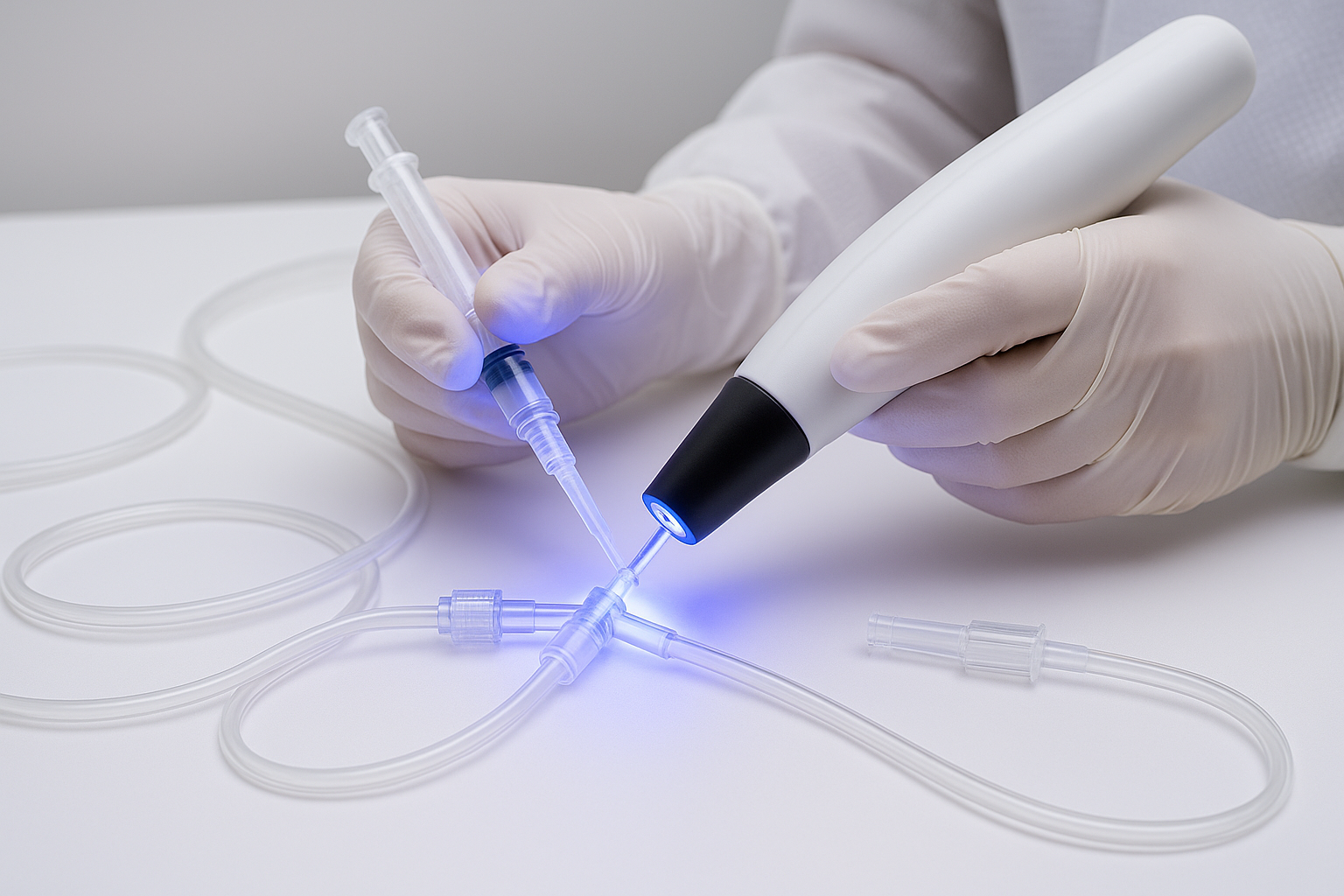

These solvent-free, light-curable adhesive systems are used by leading manufacturers of disposable medical devices, catheters, hearing aids, dental products, transducers, and biomedical instruments. Each formulation is designed for fast, flexible bonding and long-term durability, ensuring performance in even the most demanding medical environments.

Why Choose OPTIMAX® Medical-Grade UV Adhesives

Our UV-curable resin systems have been developed to satisfy the stringent needs of medical production lines that require:

-

Instant UV curing – Bonds form in seconds under ultraviolet light.

-

Solvent-free formulations – No volatile organic compounds, no contamination risk.

-

Crystal-clear finish – Transparent, high-strength joints ideal for medical plastics.

-

Wide material compatibility – Bonds to PC, PVC, PMMA, PU, ABS, stainless steel, aluminium, and glass.

-

Autoclave resistance – Maintains integrity after sterilisation and thermal cycling.

-

Fluorescing inspection options – Enables fast in-line quality control for high-volume production.

Whether you’re producing syringes, balloon catheters, Y-connectors, or diagnostic housings, OPTIMAX® adhesives combine speed, safety, and precision to optimise your production process.

Certified for Biocompatibility and Safety

Every OPTIMAX® formulation is tested to meet both ISO 10993-5 and USP Class VI requirements for cytotoxicity and biocompatibility — providing confidence for use in medical, dental, and biomedical applications. This makes NovaChem one of the few suppliers in the UK offering a fully proven group of resin systems tested to these rigorous standards.

Tailored Solutions and Technical Support

No two production lines are identical. NovaChem’s custom-formulating service ensures your adhesive performs exactly as your process demands.

Our design and engineering specialists work directly with your R&D or production teams to:

-

Identify curing speed, bond strength, and material requirements.

-

Optimise viscosity and flexibility for automated dispensing or manual assembly.

-

Provide recommendations for UV wavelength, exposure time, and line integration.

This collaborative approach allows us to deliver bespoke formulations that enhance yield, reduce waste, and maintain the highest medical-grade compliance.

Product Highlights

| Product | Description | Typical Applications | Compatible Substrates | Viscosity (cps) | Shore Hardness |

|---|---|---|---|---|---|

| 921-M-LV / 921-M / 921-M-HV | Rapid-curing adhesives for plastics and metals used in medical devices. Flexible, transparent bonds for high-speed assembly. | Needle & syringe bonding, catheters, masks, tubing, Y-connectors, balloon bonding, reservoirs. | PC, PVC, PMMA, PU, ABS, stainless steel, aluminium, glass, SAN, TPU. | 70–22,500 | D45 |

| 8967-M | Acrylic-based UV structural adhesive offering superior chemical, environmental, and water resistance. | Catheter bonding, balloon bonding, lumen sealing, transducers. | PE, stainless steel, aluminium, PVC, polyurethane, ABS, glass. | 125,000 | D40 |

| 8002-LV / 8002-HV | Rigid, fast-curing adhesives with excellent depth of cure. Ideal for potting, encapsulation, and electronic coatings. | Medical encapsulation, casting, sealing. | Multi-substrate | 100–3,200 | D85 |

| 8962 | Specialised for high-speed syringe and needle bonding. Fluoresces for in-line inspection and resists autoclaving. | Cannula-hub assemblies, syringes, lancets. | PP, PE, stainless steel, PC. | 300 | D45 |

| 8198 | Flexible thermoplastic adhesive providing high-strength bonds between rigid PVC and polycarbonate. | Tube sets, reservoirs, oxygenators, masks, electronics. | PE, stainless steel, PVC, ABS, glass. | 5,500 | D65 |

Designed for Medical Excellence

OPTIMAX® adhesives have become the trusted choice for UK manufacturers seeking precision bonding without compromise. Each product offers a balance of speed, flexibility, and performance — all while supporting compliance with FDA Class VI and ISO 10993 testing standards.

By reducing curing times from minutes to seconds, our UV systems enhance throughput, minimise handling, and improve consistency across production lines.

Partnering with NovaChem UK

From material selection and surface preparation to UV source specification and line optimisation, NovaChem provides end-to-end technical guidance to ensure every bond performs as expected. Our adhesives are supplied with full technical data, safety documentation, and application support.

If you’re looking to improve assembly speed, increase product reliability, or meet strict biocompatibility standards, NovaChem’s OPTIMAX® range provides the performance and assurance you need.

Call: +44 (0)203 519 2209

Email: sales@novachem-uk.co.uk